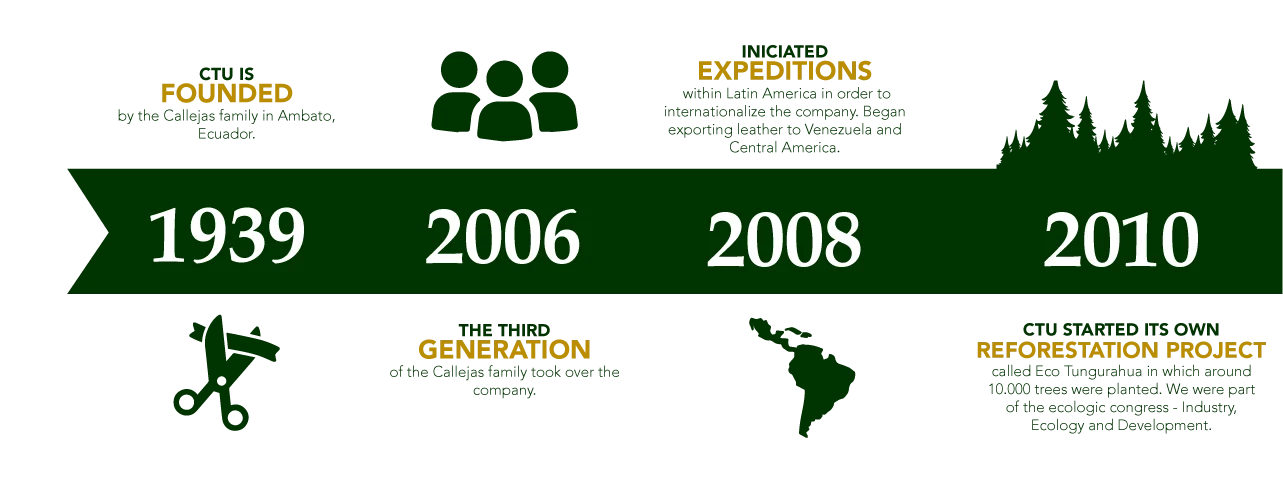

ABOUT US

PASSION

We’re here to create value for our customers, value for our employees, and value for society.

We also dream of living in a world where we don’t abuse what gives us life.

Yes, we dream. But we know that dreaming is not enough. That is why we have created processes and products that take care of the planet; we fight for our passion -leather- and we work everyday with effort to create the opportunities that we dream of.

LEGACY

creating memories

OUR

TANNERY

BEFORE

OUR

TANNERY

AFTER

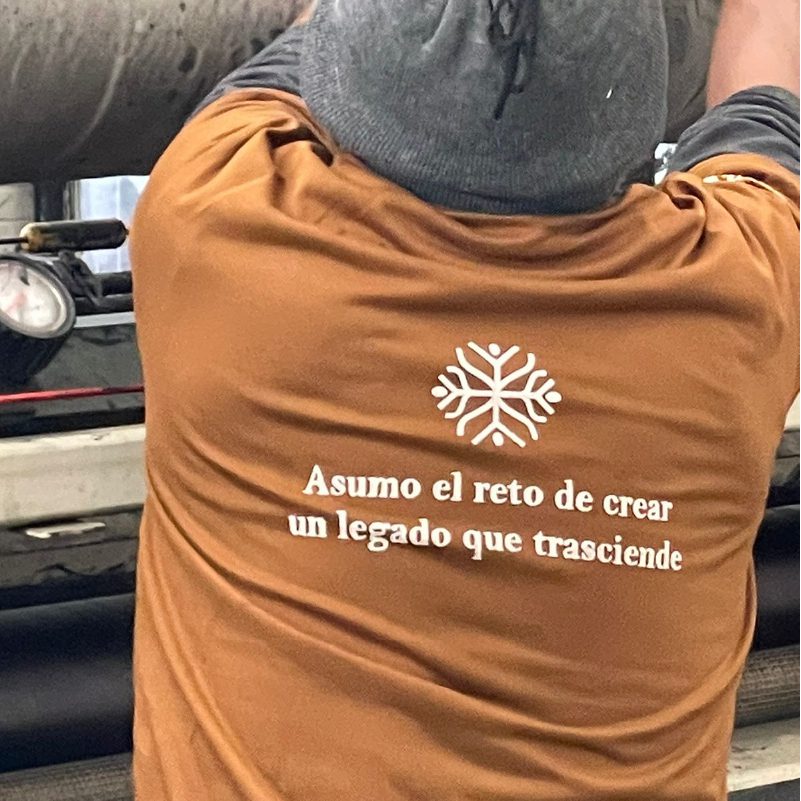

HUMAN

CARE

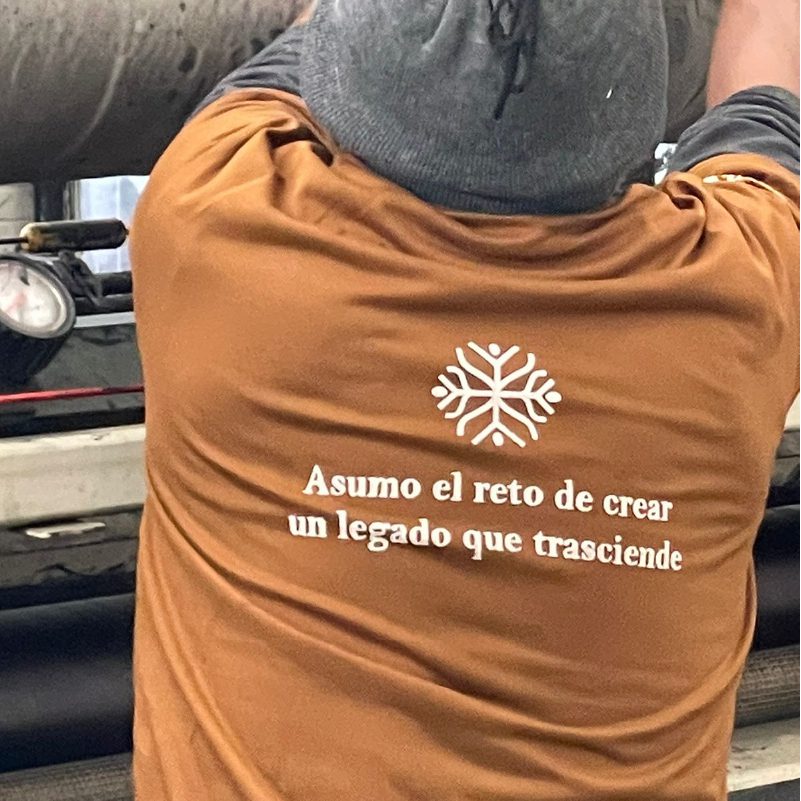

Our 153 family members contribute with their joy, care and passion for life and leather.

Yes, leather is the coolest material, but what would happen to the leather industry without the handcrafters behind the art? It wouldn’t exist. The leather industry helps the planet, but it’s people that make it happen.

How do we take

care of

our people?

Health & safety:

We take care of our family.

PLANET

CARE

Find out more about our planet care initiatives:

INNOVATION

&TECHNOLOGY

Water Homogenization

All water hardness and other possible contaminants are homogenized prior to being used in our plant. This allows us to significantly improve the water quality of our tanning process.

Liming process

The splitting machine has a caliber adjustment system that reduces the amount of scraping that is wasted and thus increases the production of by-product generated in the unhairing process.

Wet area or tannery

We work endlessly to find suppliers with the best technologies in the process of manufacturing the chemical products used in the tannery.

Dyeing zone

Our plant has acquired a 30% of polypropylene drums for this stage (we plan to increase that number in the near future) that process 3x more kilos and use 50% less energy. This results in a greater production capacity with less energy consumption.

Finishing area

We have state-of-the-art GEMATA painting machines, with infrared tunnels that consume less steam, therefore less energy to provide a more efficient finishing process.

Wastewater Treatment plant

We’re the first and only tannery in Ecuador that has implemented a Wastewater Treatment Plant to clean all the water we use along our process before it flows back to its natural course.

our recent

achievements

PASSION

We’re here to create value for our customers, value for our employees, and value for society.

We also dream of living in a world where we don’t abuse what gives us life.

Yes, we dream. But we know that dreaming is not enough. That is why we have created processes and products that take care of the planet; we fight for our passion -leather- and we work everyday with effort to create the opportunities that we dream of.

LEGACY

creating memories

OUR

TANNERY

BEFORE

OUR

TANNERY

After

HUMAN

CARE

Our 153 family members contribute with their joy, care and passion for life and leather.

Yes, leather is the coolest material, but what would happen to the leather industry without the handcrafters behind the art? It wouldn’t exist. The leather industry helps the planet, but it’s people that make it happen.

How do we

take care of

our people?

Health & safety:

We take care of our family.

PLANET

CARE

INNOVATION

&TECHNOLOGY

Water Homogenization

All water hardness and other possible contaminants are homogenized prior to being used in our plant. This allows us to significantly improve the water quality of our tanning process.

Liming process

The splitting machine has a caliber adjustment system that reduces the amount of scraping that is wasted and thus increases the production of by-product generated in the unhairing process.

Wet area or tannery

We work endlessly to find suppliers with the best technologies in the process of manufacturing the chemical products used in the tannery.

Dyeing zone

Our plant has acquired a 30% of polypropylene drums for this stage (we plan to increase that number in the near future) that process 3x more kilos and use 50% less energy. This results in a greater production capacity with less energy consumption.

Finishing area

We have state-of-the-art GEMATA painting machines, with infrared tunnels that consume less steam, therefore less energy to provide a more efficient finishing process.

Wastewater Treatment plant

We’re the first and only tannery in Ecuador that has implemented a Wastewater Treatment Plant to clean all the water we use along our process before it flows back to its natural course.

our recent

achievements